Number of parallel paths

The winding of an electrical machine can be split into a certain number of parallel paths in order to adjust the voltage and current ratings to those of a specific supply.

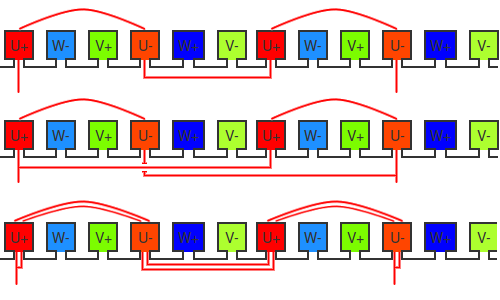

Fig. 1. shows two different ways in order to change a winding where all coil are connected in series to a winding layout with two parallel paths. When splitting up the phase windings into parallel paths, make sure that the different paths are identical (equal number of turns, equal resistance, exposed to equal flux in any rotor position, etc.) in order to avoid undesirable imbalances. Using the second approach (Fig. 1 bottom), any number of parallel paths can be achieved that are feasible from a practical point of view.

Fig. 1 Illustration of a winding configuration with different number of parallel paths. All coils are series-connected (top), two coils are connected in parallel creating two parallel paths (middle), or all coils are series-connected, but internally split up into two parallel paths (bottom).

The following table shows that the number of parallel paths does allow to adjust the voltage and current ratings of the motor to those of a specific supply, without changing the performance of the motor otherwise. Another way to adjust the voltage and current rating is to change between Delta and Star connection of the winding terminals.

| Property | Series-connected coils | Two parallel paths |

| Torque | 1 p.u. | 1 p.u. |

| Output power | 1 p.u. | 1 p.u. |

| Phase current | 1 p.u. | 2 p.u. |

| Phase resistance | 1 p.u. | 0.25 p.u. |

| Current density | 1 p.u. | 1 p.u. |

| Copper losses | 1 p.u. | 1 p.u. |

| Phase voltage | 1 p.u. | 0.5 p.u. |

Read about another glossary term